How to choose weld on rail shoulders

There are many types of weld on rail shoulders, and various factors need to be considered when selecting rail shoulders to ensure that they meet the specific requirements of railway infrastructure and operational needs. How should we choose rail shoulders? Let us follow the Chinese rail shoulder manufacturers to find out

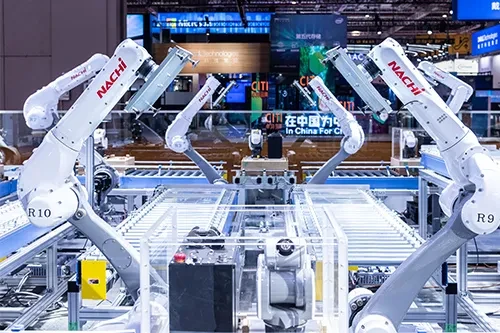

Our latest projects

Shanghai Jwell machinery Workshop co-operation projects

Material and rail type

weld on rail shoulders are usually made of materials such as cast iron, steel or composite materials. Material selection depends on factors such as track type, operating conditions (e.g. temperature, humidity) and required durability.weld on rail shoulders are widely used due to their strength and wear resistance; consider the type and size of the rail when selecting weld on rail shoulders . Different rail profiles may require specific types of weld on rail shoulders , make sure the rail shoulders have the correct profile and size to match the rail profile and provide proper support. For example, flat bottom rails may require different rail shoulders compared to grooved or vignole rails.

Carrying capacity and compatibility

Determine the expected load and traffic volume on the railway line to select shoulders with appropriate carrying capacity. The rail shoulder should be able to support the weight of the rail, rolling stock and any additional loads without suffering excessive deformation or stress; ensure the shoulder is compatible with other components of the railway infrastructure, such as railway fasteners, sleepers and ballast. Compatibility is critical to the correct installation and performance of track systems.

Environmental conditions and regulatory compliance

Depending on the environment, we need to consider the environmental conditions for installing the road shoulder, including factors such as temperature changes, humidity, and exposure to chemicals or pollutants. Select weld on rail shoulders that are resistant to corrosion, weathering and other environmental factors to ensure long-term durability; we ensure that the selected weld on rail shoulders comply with relevant industry standards, regulations and specifications. This includes standards for materials, dimensions, performance and safety requirements set by organizations such as railway authorities and industry associations.